Technologies that realize Art line image quality in a zoom lens

FLD glass, SLD glass, and high-refractive index,high-dispersion glass help minimize aberrations.

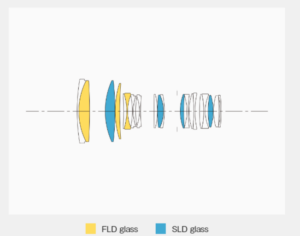

To help minimize axial and transverse chromatic aberration, this lens features an optimal arrangement of three

FLD (“F” Low Dispersion) glass elements, one SLD (Special Low Dispersion) glass element, three high-refractive index SLD glass elements, and one high-refractive index, high-dispersion glass element. By including one or more low-dispersion element in every element group, this lens ensures outstanding image quality throughout the zoom and focal range.

Featuring a newly designed

Hyper Sonic Motor

To achieve outstanding image quality and F1.8 brightness, SIGMA has enhanced its Hyper Sonic Motor (HSM). Optimizing the layout as well as the shapes of the individual parts, SIGMA has made the HSM 30 percent slimmer than before. In turn, this slimmer HSM has made possible the combination of F1.8 brightness and high image quality in a zoom lens. As with the previous SIGMA HSM, at any time during AF, users may access MF simply by rotating the focus ring. This feature makes faster focus adjustment possible, since there is no need to use the AF/MF focus mode switch. Also, the optional SIGMA USB DOCK allows the user to set the lens to conventional full-time manual focus override.

Note: The operation of full-time MF may vary based on mount type.

Diaphragm unit designed for smooth operation

The diameter of the diaphragm is the second-largest in the SIGMA lens lineup after that of the SIGMA 200-500mm F2.8 /400-1000mm F5.6 EX DG, necessitating smoother and quicker operation than ever before. To achieve this goal, the diaphragm blades feature Carbon Feather film, and the diaphragm unit features a new polycarbonate made with fluorine. Thanks to these innovations, diaphragm operation is exceptionally smooth even during continuous shooting, while the new polycarbonate is exceptionally durable and wear-resistant.

Designed to minimize flare and ghosting

From the start of the design process, SIGMA measured flare and ghosting to establish an optical design that is resistant to strong incidental light sources such as backlight. At the prototyping stage, SIGMA used not only simulations but actual photographic experiments to assess flare and ghosting under multiple criteria, identify the causes of these issues under a wide range of situations, and take measures to mitigate them. In addition, SIGMA’s Super Multi-Layer Coating helps further reduce flare and ghosting and provide sharp, high-contrast images even in backlit conditions.